Technicial Specifications

| Engine Model | Cat® C18 Diesel Engine with ACERT™ Technology Cat® C18 Diesel Engine with ACERT™ Technology |

| Bore | 5.71 in 145 mm |

| Stroke | 7.2 in 183 mm |

| Displacement | 1105 in³ 18.1 l |

| Net Power - 1,800 rpm - 80/1269/EEC | 530 HP 390 kW |

| Net Power - ISO 14396 | 537 HP 401 kW |

| Net Power - 1,800 rpm - ISO 9249 | 530 HP 390 kW |

| Gross Power - SAE J1995 | 553 HP 412 kW |

| Swing Speed | 6.4 rpm 6.4 rpm |

| Swing Torque | 191766 lb/ft 260 kN·m |

| Track Width - Standard | 25.6 in 650 mm |

| Track Width - Optional | 29.5 in 750 mm |

| Number of Shoes - Each Side | 47 47 |

| Number of Carrier Rollers - Each Side | 3 3 |

| Number of Track Rollers - Each Side | 8 8 |

| Fuel Tank | 327.6 gal (US) 1240 l |

| Cooling System | 26.7 gal (US) 101 l |

| Engine Oil | 17.2 gal (US) 65 l |

| Final Drive - Each | 5.6 gal (US) 21 l |

| Hydraulic System - Including Tank | 262.9 gal (US) 995 l |

| Hydraulic Tank | 214 gal (US) 810 l |

| Swing Drive - Each | 5.02 gal (US) 19 l |

| Operating Weight - With 5.7 m3 Rock Bucket, 650 mm Shoes | 199739 lb 90600 kg |

| Maximum Drawbar Pull | 133087 lb 592 kN |

| Maximum Travel Speed | 2.8 mile/h 4.5 km/h |

| Cylinders - Stick - Bore | 8.66 in 220 mm |

| Pilot - Relief Valve Setting - Controls | 595 psi 41 bar |

| Cylinders - Master - Bore | 5.98 in 152 mm |

| Main/Travel - Number of Main Pumps | 2 2 |

| Main/Travel - Relief Valve Setting - Main | 4641 psi 320 bar |

| Cylinders - Master - Stroke | 76.89 in 1953 mm |

| Cylinders - Bucket - Bore | 7.01 in 178 mm |

| Cylinders - Boom - Stroke | 55.71 in 1415 mm |

| Pilot - Circuit | Open center Open center |

| Pilot - Maximum Flow at Rated Speed | 23.8 gal/min 90 l/min |

| Cylinders - Bottom Dump - Stroke | 10.83 in 275 mm |

| Swing - Maximum Flow at Rated Speed (Total) | 118.9 gal/min 450 l/min |

| Cylinders - Bottom Dump - Bore | 6.3 in 160 mm |

| Main/Travel - Maximum Flow at Rated Speed | 2 × 490 L/min 2 × 490 L/min |

| Pilot Pump | Gear Gear |

| Main/Travel - Pump | Piston, variable Piston, variable |

| Swing - Number of Swing Pumps | 1 1 |

| Cylinders - Stick - Stroke | 73.03 in 1855 mm |

| Swing - Relief Valve Setting - Accelerating | 3771 psi 260 bar |

| Main/Travel - Relief Valve Setting - Travel | 5076 psi 350 bar |

| Swing Pump | Piston, variable Piston, variable |

| Swing Circuit | Open center, load sensing Open center, load sensing |

| Cylinders - Bucket - Stroke | 71.26 in 1810 mm |

| Pilot - Number of Pilot Pumps | 1 1 |

| Cylinders - Boom - Bore | 7.09 in 180 mm |

| Main/Travel - Circuit | Closed center, load sensing Closed center, load sensing |

| Standards | Standards Standards |

| Exterior Sound | Standards Standards |

| Operator Sound | Standards Standards |

Advantages and Features

Engine

Diesel Engine

The Cat C18, with ACERT Technology, is an 18.1 L, six‑cylinder, 390 kW (530 hp) engine with mechanically actuated electronic fuel injection (MEUI) and overhead camshaft. ACERT Technology provides outstanding engine performance through advanced electronic control, precision fuel delivery, and refined air management.

Fuel Consumption

The Advanced Diesel Engine Management (A4) controller uses sensors throughout the engine to manage engine load and performance. The A4 controller is the muscle behind engine responsiveness, self-diagnostics, controlling emissions, and fuel economy.

Fuel System

The MEUI system combines high-pressure injection and electronic control in a single compact unit. The electronic unit injector is an integral part of the C18 fuel system. Computerized electronic control provides precise metering and timing of fuel injection.

Cooling System

High-capacity, side‑by‑side cooling system allows operation in ambient temperatures up to 52° C. The Electric Power Control (EPC) controls the fan speed based on coolant temperature and hydraulic oil temperature for optimized cooling.

Turbocharger

The C18 engine uses a water-cooled, center-section waste gated turbocharger for improved performance. This turbocharger controls the air volume to the cylinders and works efficiently during low and high load conditions.

Emissions

ACERT Technology is a differentiated technology that reduces emissions at the point of combustion. The technology capitalizes on proven Caterpillar leadership in three core engine systems: fuel, air, and electronics.

Cold Weather Starting Kit

The kit consists of two additional batteries, heavy-duty harness, large capacity starting motor, and the ether starting aid. With this kit, the excavator has the capability to start at –32° C.

Environmentally Responsible Design

Outstanding Performance

Many features are designed to provide outstanding performance, which can mean more work done in a day, less fuel consumption, and minimal impact on our environment.

Low Exhaust Emissions

The Cat C18 diesel engine utilizes unique ACERT Technology to meet exhaust emissions regulations while assuring optimum fuel efficiency.

Quiet Operation

The hydraulically driven cooling fan is thermostatically controlled so the fan only runs at the speed necessary to maintain correct system operating temperatures. The result is cool, quiet operation with less disturbance to the surrounding environment.

Ozone Protection

To help preserve the earth's ozone layer, the air conditioning unit uses only R-134a refrigerant, which does not contain harmful chlorofluorocarbons (CFC's).

Fewer Leaks and Spills

Engine oil and encapsulated hydraulic oil filters are positioned vertically and are easy to reach to minimize spillage. Service intervals are extended to reduce the times fluids are changed and handled. The new hydraulic oil fine filtration system attachment extends the service interval from 2,000 to 5,000 hours. Compatible with Cat HEES hydraulic bio-oil for ecologically sensitive applications. Finally, the new Cat Extended Life Coolant extends service (up to 6,000 hours) so there is less need for fluid disposal.

Undercarriage and Structures

Track

New grease-lubricated track called GLT4 comes standard. Track links are assembled and sealed with grease to decrease internal bushing wear, reduce travel noise, and extend service life to lower operating costs.

Track Roller Frame

A longer recoil spring improves durability and service life of the undercarriage; an offset idler increases stability while working over the front of the machine.

Forged Idler

The more durable forged idler is standard on 385C front shovel.

Idler Guards and Track Guides

Idler guards and center track guides to maintain track alignment are standard. Optional two-piece full‑length track guiding guards are available.

Positive Pin Retention 2 (PPR2)

PPR2 track link is standard. PPR2 is designed to prevent looseness of the track pin in the link, which reduces stress, eliminates pin walking, and increases service life.

Final Drives

The three-stage reduction planetary type final drives function as a compact drive/brake unit that delivers excellent performance and reliability.

Carbody Design

The X-shaped, box-section carbody provides excellent resistance to torsional bending. The upper structure weight and stresses are distributed evenly across the full length of the track roller frame. Robot welding ensures consistent, durable welds.

Travel Motors

Two-speed axial piston hydraulic motors provide drive power. Speed selection is automatic when the high-speed position is selected. Travel motors have internal disk brakes to hold the machine when stationary, and the motors are protected from damage by rigid covers.

Upper Frame

The rugged main frame is designed for maximum durability. Box-section channels improve upper frame rigidity. A new boom foot design transfers load more efficiently with less stress in critical areas. Also, reinforced lift cylinder and swing drive mounts increase structure durability in rock and quarry applications.

Hydraulics

Hydraulic System

The hydraulic system includes a three-pump system with an independent swing circuit and a hydraulic circuit utilizing the proven Proportional Priority Pressure Compensated (PPPC) system. Cat electronic control and activation ensures high hydraulic system efficiency and excellent productivity.

PPPC System

The PPPC system provides many advancements. Cylinder speed is directly related to the operator's movement of the joystick from feathering to full speed. Flow to cylinders during multi-functional operation is directly controlled by the operator and is not dependent on loads. Also, the controller reduces pump output to save power when joysticks are in the neutral position.

Power Management Control

The pump valve electronic controller is central to power management control and provides highly efficient control for the pumps, valves, and engine.

Swing Performance

The three-pump system with independent swing gives priority to the swing circuit for strong swing acceleration and easily controlled multi-function operation.

Component Layout

The hydraulic pumps, control valve, and hydraulic tank are close together to minimize piping length. The swing control valve is mounted directly on the swing motor. Main and swing pump suction and discharge lines have large diameters, which combine with the component layout to guarantee high efficiency.

Auxiliary Hydraulics

An auxiliary valve is standard and is used for the bottom dump circuit. It is driven electrically based on commands from the pump valve controller.

Front Linkage Hydraulic System

The hydraulic system for the implement consists of two boom cylinders, a stick cylinder, two bucket cylinders, two bottom dump cylinders, and a master cylinder.

Hydraulic Oil Filtration System

The hydraulic system features six standard filters. These filters improve reliability, extend the life of hydraulic equipment and hydraulic oil, boost performance, and reduce running costs. A fine filtration system is available as an attachment.

Front Linkage

Parallelogram Linkage

The Cat 385C FS Front Shovel features parallelogram-type front linkage with a master cylinder. The linkage automatically keeps the bucket parallel to the ground. This allows excellent penetration, fast loading, and a smooth floor cleanup. The operator can concentrate on the boom and stick rather than bucket adjustments. The master cylinder circuit automatically maintains a level bucket while raising the boom. It aids in bucket positioning both above and below grade, eliminating constant adjustment during the work cycle. The master cylinder arrangement also uses bucket cylinder circuit pressure to increase the boom lifting force.

Boom

The boom is 4.6 m long and features a rigid structure with a number of steel castings. The cast-steel portions are structured into a box to reduce the weight of the boom nose and boom foot.

Stick

The 385C FS offers a 3.4 m long stick. The stick nose and stick foot are made of cast steel. The middle portion has a box structure fabricated with steel plates. The stick cylinder mounting bracket is reinforced from the inside.

Bottom Dump Bucket

The recommended bucket for the 385C FS is a bottom dump bucket. It is designed for strength, performance, and long service life.

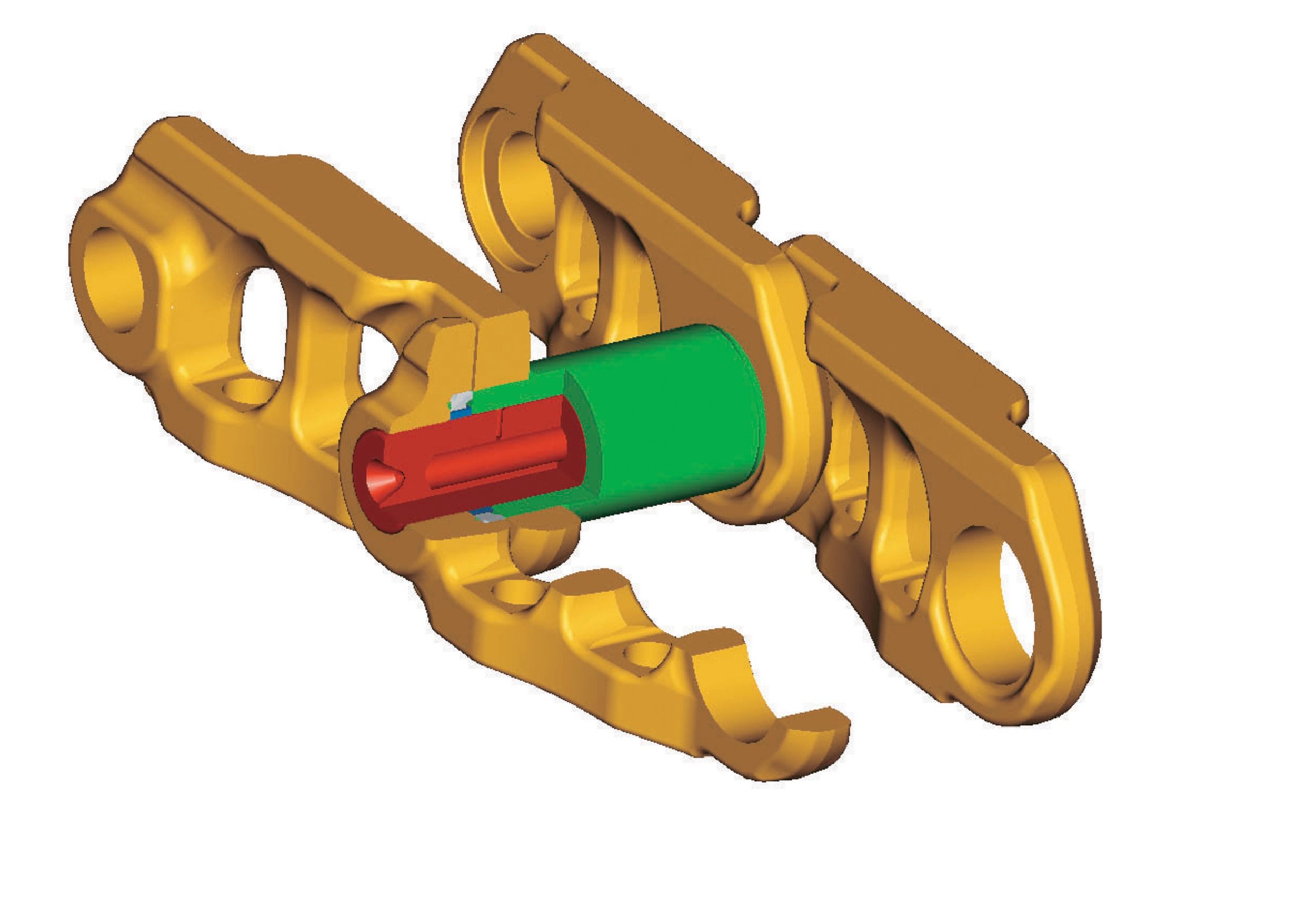

Linkage Pin

All pins used in the 385C FS front linkage have thick chrome plating, giving them high wear and corrosion resistance. The diameter of each pin is made as large as possible to smoothly distribute the shear and bending loads associated with the digging and lifting forces.

Operator Station

Cab Design

The workstation has been designed to be spacious, quiet, and comfortable for the operator, assuring high productivity throughout the entire workday. Switches are conveniently located for easy access. The monitor is located to provide excellent visibility and access.

Seat

The seat provides a variety of adjustments, including fore/aft, height and weight to suit the operator. Also included are adjustable armrests and a retractable seat belt. For additional comfort, a new heated air suspension seat is available as an attachment.

Skylight

An enlarged skylight with sunshade provides excellent visibility and good ventilation.

Hydraulic Activation Control Lever

The hydraulic activation control lever deactivates hydraulic functions during engine startup and prevents unintentional machine operation.

Climate Control

Positive filtered ventilation with a pressurized cab comes standard. Fresh air or recirculated air can be selected with a switch on the left console.

Windows

To maximize visibility, all glass is affixed directly to the cab, eliminating the use of window frames. A choice of fixed or easy-to-open split front windshield meets operator preference and application conditions.

- 50/50 split front windshield allows both upper and lower portions to be stored in an overhead position.

- 70/30 split front windshield stores the upper portion above the operator. The lower front windshield features a rounded design to maximize downward visibility and improves wiper coverage.

- Both openable versions feature a one-touch action release system.

- The fixed front windshield is available in standard-duty laminated glass or high-impact-resistant laminated glass.

Wipers

Parallelogram wiper, including a washer nozzle, is mounted below the cab windshield, optimizing the operator's viewing area and offering continuous and intermittent modes.

Monitor

The compact, full-color monitor has functions to display machine, maintenance, diagnostic, and prognostic information. The angle of the monitor can be adjusted to face the operator and prevent sun glare.

Cab Exterior

The exterior design uses thick steel tubing along the bottom perimeter of the cab, improving the resistance of fatigue and vibration. This design allows the FOGS to be bolted directly to the cab at the factory or as an attachment later, enabling the machine to meet specifications and job site requirements.

Cab Mounts

The cab shell is attached to the frame with viscous rubber cab mounts, which dampen vibrations and sound levels while enhancing operator comfort.

Cab Riser

To provide excellent forward visibility for truck loading and other applications, an 870 mm cab riser is standard on the 385C Front Shovel.

Consoles

Redesigned consoles feature a simple, functional design to reduce operator fatigue, ease of switch operation, and excellent visibility. Both consoles have attached armrests and allow the height of the armrests to be adjusted.

Standard Cab Equipment

To enhance operator comfort and productivity, the cab includes a lighter, drink holder, coat hook, service meter, literature holder, magazine rack, and storage compartment. The cab can be equipped with optional 12 volt converter and up to two 12V-7 amp electrical sockets to provide additional electrical resources.

Machine Security

An optional Machine Security System (MSS) is available from the factory. MSS uses a special Cat key with an embedded electronic chip for controlling unauthorized machine operation.

Product Link

The machine comes Product Link ready from the factory.

Electronic Control System

Monitor Display Screen

The monitor is a full-color 400 × 234 pixels Liquid Crystal Display (LCD) graphic display. The Master Caution Lamp blinks ON and OFF when one of the critical conditions below occurs:

- Engine oil pressure low

- Coolant temperature high

- Hydraulic oil temperature high

Clock and Throttle Dial Display

The clock, throttle dial, and gas station icon with green color are displayed in this area.

Gauge Display

Three analog gauges – fuel level, hydraulic oil temperature, and coolant temperature – are displayed in this area.

Event Display

Machine event information is displayed in this area along with the icon and language.

Multi-information Display

This area is reserved for displaying information that is convenient for the operator. The Cat logo is displayed when no information is available to display.

Operator Gain/Response

This is used to suit the operator's preference or application.

- Quicker for fast response and more production

- Slower for more precision

- Three preset settings with 21 available settings

Electronic Joysticks

Electronic joysticks provide features not possible with hydraulic pilot valves:

- Eliminate pilot lines in cab for quieter operation

- Adjustable gain/response

Service and Maintenance

Service Points and Intervals

Service points are centrally located with easy access to facilitate routine maintenance. Service intervals for engine oil and oil and fuel filters extend to 500 hours to reduce maintenance costs.

Oil Sample and Pressure Ports

Oil sample and pressure ports provide easy checking of machine condition and are standard on every machine.

Hydraulic Capsule Filters

The return filters or capsule filters for the hydraulic system are located beside the hydraulic tank. The filter elements are removable without spilling hydraulic oil.

Remote Greasing Block

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Radial Seal Cleaner

Radial seal main air cleaner with precleaner has a double-layered filter element for more efficient filtration. No tools are required to change the element.

Fuel-Water Separator

The water separator removes water from fuel, even when under pressure, and water level can be monitored in the cab.

Complete Customer Support

Machine Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments, and operating hours? What production is needed? Your Cat dealer can provide recommendations.

Purchase

Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan the best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has videotapes, literature, and other ideas to help you increase productivity, and Caterpillar offers certified operator training classes to help maximize the return on your investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. You can save money with Cat remanufactured components.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as scheduled oil sampling, coolant sampling, and technical analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Standard Equipment

-

Electrical

- Alternator – 75 amp

- Lights working

- Signal/warning horn

-

Engine/Powertrain

- Air filter with precleaner

- Automatic engine speed control

- Automatic swing parking brake

- Automatic travel parking brakes

- Cat C18 ATAAC with ACERT Technology, altitude capability to 2300 m without derating

- Fuel filter

- High ambient cooling, 52° C capability

- Side-by-side cooling system with separately mounted AC condenser and variable speed fan

- Two speed travel

- Water separator, with level indicator, for fuel line

-

Guards

- FOGS (Falling Object Guard System) including overhead and windshield guards

- Heavy duty bottom guards on upper frame

- Heavy duty swivel guard on undercarriage

- Heavy duty travel motor guards on undercarriage

- Idler and center section track guiding guards

- Quarry application (cylinder guard, swing motor and drive guard)

-

Operator Station

- Adjustable armrest

- Air conditioner, heater and defroster with automatic climate control

- Ashtray and 24 volt lighter

- Beverage/cup holder

- Cab riser 870 mm

- Capability to install 2 additional pedals

- Coat hook

- Console mounted electronic type joysticks with adjustable gain and response

- Electrical provision for seat heater

- EU sound criteria package

- Floor mat, washable

- High resistant cab window

- Instrument panel and gauges with full color graphical display, start up level checks

- Joystick, thumb wheel modulation joystick for use with front shovel bottom dump bucket

- Literature compartment

- Neutral lever (lock out) for all controls

- Positive filtered ventilation, pressurized cab

- Rear window, emergency exit

- Retractable seat belt 51 mm width

- Sliding upper door window

- Stationary skylight (polycarbonate)

- Storage compartment suitable for lunch box

- Sunshade for windshield and skylight

- 24V radio ready (harness, 2 speakers, flexible type antenna)

- Travel control pedals with removable hand levers

- Utility space for magazines

- Windshield wipers and washers (upper and lower)

- Windshield one-piece high impact resistant

-

Undercarriage

- 650 mm clipped double grouser shoes, standard length, variable gauge

- Grease lubricated track GLT 4

- Hydraulic track adjusters

- Steps – four

-

Other Standard Equipment

- Boom and stick reducting valve

- Cat branded XT hoses

- Cat batteries

- Cat one key security system with locks for doors, cab and fuel cap

- Cat walks – left side and right side

- Cross-roller type swing bearing

- Heavy lift mode

- High pressure cut off

- Hydraulic circuit for bottom dump bucket

- Mirrors – left and right

- S·O·SSM quick sampling valves for engine oil and hydraulic oil

- Steel firewall between engine and hydraulic pumps

- Wiring provisions for Product Link, Auto‑lube System and lighted beacon

Optional Equipment

-

Front Linkage

- Boom 4600 mm

- Stick 3480 mm

- Buckets (see Buckets for K Series™ Tooth System)

- Tips, cutting edge protection segments, and sidebar protector

-

Track

- Double grouser shoes 750 mm

-

Guards

- Track guiding guards

-

Miscellaneous Options

- Auto-lubrication device including boom and stick (not bucket)

- Bio-degradable hydraulic oil (saturated, synthetic ester, 5,000 hours change interval)

- Converters, 7 amp – 12V

- Counterweight removed device

- Electric refueling pump without shut off

- Fast fill engine oil system

- Fast fill fuel system

- Fine filtration filter

- Hydraulic tank shut-off valve

- Jump start terminals

- Oil quick change system

- Radiator screen

- Reversible cooling fan including protective screen

- Starting aid for cold weather with ether

- Stick lowering control device

- Travel alarm with cut off switch

-

Operator Compartment

- Lunch box storage with lid

- Machine security system with programmable keys

- Radio

- Seat

- Straight travel pedal