Technicial Specifications

| Base Power (1st Gear) - Net | 171 hp 128 kW |

| Engine Model | Cat C7 Cat C7 |

| Displacement | 439 in³ 7.2 l |

| Bore | 4.1 in 105 mm |

| Stroke | 5 in 127 mm |

| High - Ambient Capability | 122 °F 50 °C |

| Maximum Torque | 735 ft-lb 996 N·m |

| Note (3) | Maximum torque measured at 1,000 rpm in gears 4-8. Maximum torque measured at 1,000 rpm in gears 4-8. |

| VHP Range - Net | 128-143 kW (171-191 hp) 128-143 kW (171-191 hp) |

| Number of Cylinders | 6 6 |

| Torque Rise | 46% 46% |

| Note (1) | Net power is tested per ISO 9249, SAE J1349, and EEC 80/1269 standards in effect at the time of manufacture. Net power is tested per ISO 9249, SAE J1349, and EEC 80/1269 standards in effect at the time of manufacture. |

| Derating Altitude | 10000 ft 3048 m |

| Note (2) | Net power advertised is the power available at rated speed of 2,000 rpm, measured at the flywheel when engine is equipped with fan, air cleaner, muffler and alternator. Net power advertised is the power available at rated speed of 2,000 rpm, measured at the flywheel when engine is equipped with fan, air cleaner, muffler and alternator. |

| Operating Weight - Typically Equipped | 38076 lb 17271 kg |

| Gross Vehicle Weight - Typically Equipped - Rear Axle | 27193 lb 12335 kg |

| Gross Vehicle Weight - Base - Rear Axle | 23128 lb 10491 kg |

| Gross Vehicle Weight - Base - Total | 32518 lb 14750 kg |

| Gross Vehicle Weight - Base - Front Axle | 9390 lb 4259 kg |

| Gross Vehicle Weight - Typically Equipped - Total | 38076 lb 17271 kg |

| Gross Vehicle Weight - Typically Equipped - Front Axle | 10883 lb 4936 kg |

| Gross Vehicle Weight - Typically Equipped | 38076 lb 17271 kg |

| Blade Width | 12 ft 3.7 m |

| Arc Radius | 16.3 in 413 mm |

| Throat Clearance | 4.7 in 120 mm |

| Moldboard - Height | 24 in 610 mm |

| End Bit - Thickness | 0.6 in 16 mm |

| End Bit - Width | 6 in 152 mm |

| Cutting Edge Thickness | 0.6 in 16 mm |

| Cutting Edge Width | 6 in 152 mm |

| Moldboard - Thickness | 0.9 in 22 mm |

| Moldboard Sideshift - Left | 20.2 in 512 mm |

| Circle Centershift - Right | 28.7 in 728 mm |

| Circle Centershift - Left | 29.6 in 752 mm |

| Blade Tip Range - Backward | 5° 5° |

| Maximum Lift Above Ground | 18.9 in 480 mm |

| Maximum Depth of Cut | 28.9 in 735 mm |

| Maximum Shoulder Reach Outside of Tires - Left | 74.6 in 1896 mm |

| Maximum Shoulder Reach Outside of Tires - Right | 77.9 in 1978 mm |

| Blade Tip Range - Forward | 40° 40° |

| Moldboard Sideshift - Right | 26.1 in 663 mm |

| Front Axle - Wheel Lean - Left/Right | 18° 18° |

| Front Axle - Total Oscillation per Side | 32° 32° |

| Circle - Outer Diameter | 60.2 in 1530 mm |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. |

Advantages and Features

BUILT TO PERFORM

- Cat C7 engine meets U.S. EPA Tier 3/EU Stage IIIA equivalent or Tier 2/Stage II equivalent emissions standards, depending on emission standards of specific country.

- Power Shift Countershaft Transmission matched to engine, maximizing power to the ground.

PERFORMANCE WITH LESS FUEL

- Electronic Throttle Control helps improve productivity by optimizing HP and torque to match the power demands of the application.

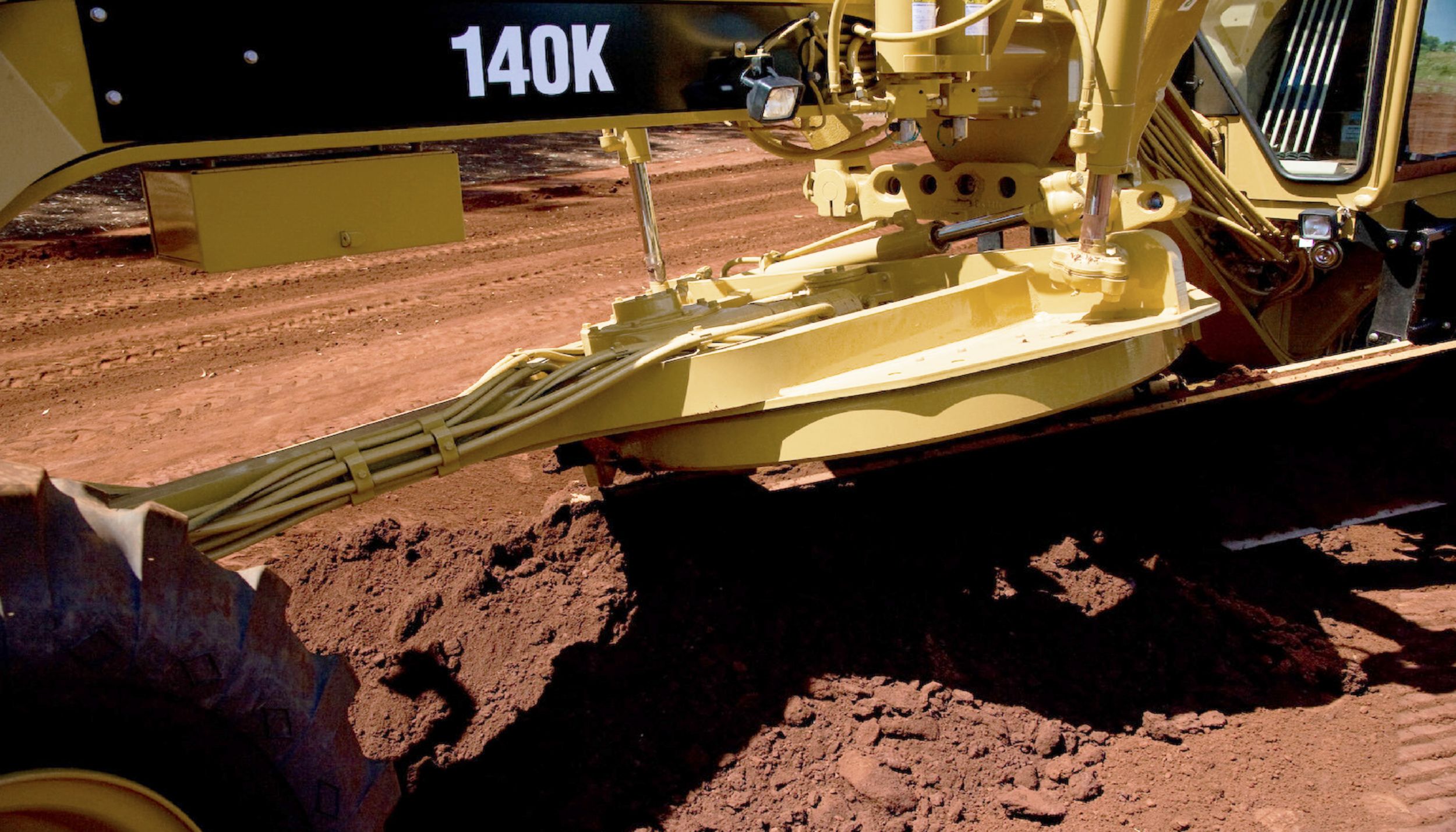

- Aggressive blade angles, optimized moldboard curvature and large throat clearance allows material to roll more freely along blade, increasing efficiency.

- Hydraulic demand fan automatically adjusts speed according to cooling requirements maximizing power to the ground and improving fuel efficiency.

- Engine Idle Shutdown is available to shut down engine after a set period of time, saving fuel and helping reduce emissions.

DESIGNED FOR OPERATORS

- Proportional Priority Pressure-Compensating (PPPC) provides load-sensing hydraulics with superior control, enhanced performance, and efficiency.

- Optional AutoShift Transmission improves ease of operation and maximizes productivity by automatically shifting the transmission at optimal shift points.

- Rocker and control switches are in easy reach.

- Proven conventional controls provide industry-standard control pattern and feel for precise cutting edge movement.

SAVE MAINTENANCE TIME

- Durable nylon composite wear inserts maximize circle torque and component life.

- Sacrificial brass moldboard slide rail wear strips between blade mounting group and moldboard can be easily adjusted and replaced.

- Left-side, ground level service area access speeds up maintenance and ensures that routine service is performed on time.

LONG TERM VALUE AND DURABILITY

- Utilizing rigorous component design and machine validation processes results in unmatched reliability, durability and high uptime.

- Components are designed and manufactured to Caterpillar quality standards throughout all Caterpillar facilities.

WORK IN COMFORT

- Optional HVAC, defroster fan and sun shades keep you comfortable, while conveniently placed power ports keep additional communication devices charged and ready.

PRODUCTIVITY WITH TECHNOLOGY

- Optional Cat Grade uses positioning and guidance technologies, machine sensors, and automatic blade control to help get to grade faster, easier, and more efficiently.

- Optional Cat Product Link™ aids your equipment management with remote monitoring capabilities.

- Attachment Ready Option (ARO) can be ordered as a factory or dealer installed option making installation of the Grade grade control system faster and easier.

BUILT-IN SAFETY FEATURES

- Brakes located at each tandem wheel offer the largest total brake surface area in the industry, delivering dependable stopping power.

- Standard circle drive slip clutch protects the drawbar, circle and moldboard from shock loads when the blade encounters an immovable object.

- Ground level engine shutoff allows anyone nearby to shut the machine down in case of an emergency.

- Built-in lock check valves

- Clear view to moldboard heel and tandem tires enhance productivity and safe operation.

- Blade Lift Accumulators help absorb impact loads to the moldboard by allowing vertical blade travel.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

Electrical

- Alternator, 115 ampere

- Backup alarm, reversing lights

- Batteries, maintenance free 750 CCA

- Common fuse block

- Electrical system, 24 volt

- Horn, electric

- Indication display

- Lights, stop and tail

- Motor, starting

- Product Link ready

- Working lights

-

Operator Environment

- Accelerator

- Control console, adjustable

- Gauge cluster (includes voltmeter, articulation, engine coolant temperature, air brake pressure and fuel level)

- Guard rails, operator station

- Hydraulic controls, load sensing (right/left blade lift, circle drive, centershift, sideshift, front wheel lean and articulation)

- Indicator lights (includes high beam, LH and RH turn, low engine oil pressure, throttle lock, check engine, transmission filter bypass and check, centershift pin, brake air pressure, parking brake engaged, auto shift)

- Key start/stop switch

- Meter, hour

- Power steering, hydraulic

- Seat, vinyl-covered static

- Seat belt

- Steering wheel, tilt, adjustable

- Storage area, cooler/lunch box

- Throttle, electronic control

-

Power Train

- Air cleaner, dry type radial seal with service indicator and automatic dust ejector

- Air to air after cooler (ATAAC)

- Blower fan

- Brakes, oil disc, four-wheel air actuated

- Differential with lock/unlock

- Eco mode

- Engine idle shutdown

- Engine, Cat C7 diesel with automatic engine derate and idle control - emits equivalent to Tier 3/Stage IIIA

- Fuel water separator

- Muffler, under hood

- Next gen filter design

- Parking brake, multi-disc, sealed and oil cooled

- Prescreener

- Priming pump, fuel, resiliently mounted

- Sediment drain, fuel tank

- Tandem drive

- Transmission, 8 speed forward and 6 speed reverse, power shift, direct drive with electronic shift control and overspeed protection

- VHP (Variable Horse Power)

-

Other Standard Equipment

- Blade Float

- Bumper, rear

- CD ROM Parts Book

- Circle drive slip clutch

- Cutting edges, 152 mm x 16 mm (6 in x 5/8 in) curved DH-2 steel

- Doors, engine compartment

- Drawbar, 6 shoe, replaceble nylon composite wear strips

- End bits, 16 mm (5/8 in) DH-2 steel

- Frame, articulated with safety lock

- Fuel tank, 305 L (80.6 gal)

- Ground level engine shutdown

- Link bar, 7 position

- SOS ports, engine, hydraulic, transmission and cooling

- Toolbox with padlock

- Vandlism protection - including cap locks for hydraulic tank, radiator access cover, fuel tank, engine and transmission oil check/fill and lockable battery boxes

-

Antifreeze

- Extended Life Coolant to -35 degrees Celcius (-30 degrees Fahrenheit)

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

Guards

- Guard, transmission

-

Operator Environment

- Air conditioner with heater

- Heater, cab

-

Cab/Canopy

- Cab, ROPS

- Cab, Non-ROPS

- Canopy, ROPS

- Seat, vinyl adjustable

- Seat, cloth, contour

- Fan, defroster, front window

- Fan, defroster, rear window

- Sun shade, rear

- Wiper/washer, rear

- Wipers, intermittent front

- Mirrors, dual inside

- Mirror, heated

- Mirrors, outside mounted

- Power port, 12V accessory

- Radio, Bluetooth

- Radio ready entertainment

- Rear vision camera

- Tachometer/speedometer

-

Ripper/Scarifier

- Ripper/scarifier, rear mounted

- Scarifier, mid mounted, V-Type

-

Lights

- Bar mounted, low, directional and headlights

- Beacon light

- Combination headlight

- Cab and bar mounted, high, directional, headlights and work lights

- Rear facing cab lights

-

Power Train

- Autoshift

-

Other Attachments

- Product Link

- Product Link Elite

- Snow Wing Mounting, frame-ready

- Cat Grade ARO

- Dryer, air

- Push plate, counterweight

- Accumulator, blade lift

- Battery, extreme duty (1,400 CCA)

- Ether, starting aid

- Heater, engine coolant, 220V

- Circle Saver

- Ripper tow package

-

Hydraulics

- Pump, hydraulic, high capacity (210 L/min, 55.7 gal/min)

- Hydraulic arrangements with one or more additional hydraulic valves are available for rear ripper, mid-mount scarifier, dozer, snow plow and snow wing

-

Blades, Moldboards

- Moldboard - Blade 4267 mm x 610 mm x 22 mm (14' x 24" x 7/8")

- Moldboard, top adjust drawbar, circle

- Blade, front

- Cutting edge, 203 mm x 19 mm (8" x 3/4") - for use with 4.3 m (14') blade

- End bits, overlay, reversible pair for use with 203 mm (8") cutting edges