Technicial Specifications

| Maximum Gross Power | 100 hp 75 kW |

| Engine Model | Cat C4.4 Cat C4.4 |

| Maximum Gross Power - Maximum Engine Speed | 2350 r/min 2350 r/min |

| Maximum Gross Power - SAE J1995 | 102 hp 76 kW |

| Maximum Gross Power - ISO 14396 | 100 hp 75 kW |

| Maximum Gross Power - ISO 14396 (DIN) | 102 hp 75 kW |

| Rated Net Power - Rated Engine Speed | 2200 r/min 2200 r/min |

| Rated Net Power - SAE J1349 | 98 hp 73 kW |

| Rated Net Power - ISO 9249 | 99 hp 74 kW |

| Rated Net Power - ISO 9249 (DIN) | 101 hp 74 kW |

| Displacement | 268 in³ 4.4 l |

| Bore | 4.13 in 105 mm |

| Stroke | 5 in 127 mm |

| Maximum Gross Torque - SAE J1995 | 306 ft·lbf 415 N·m |

| Maximum Gross Torque - ISO 14396 | 302 ft·lbf 410 N·m |

| Maximum Net Torque - SAE J1349 | 295 ft·lbf 400 N·m |

| Maximum Net Torque - ISO 9249 | 299 ft·lbf 405 N·m |

| Emissions | Engine meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3/EU Stage IIIA. Engine meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3/EU Stage IIIA. |

| Note | Net power advertised is the power available at the flywheel plus front drive implement pump when the engine is equipped with fan, air cleaner, muffler and alternator. Net power advertised is the power available at the flywheel plus front drive implement pump when the engine is equipped with fan, air cleaner, muffler and alternator. |

| Operating Weight | 18884 lb 8568 kg |

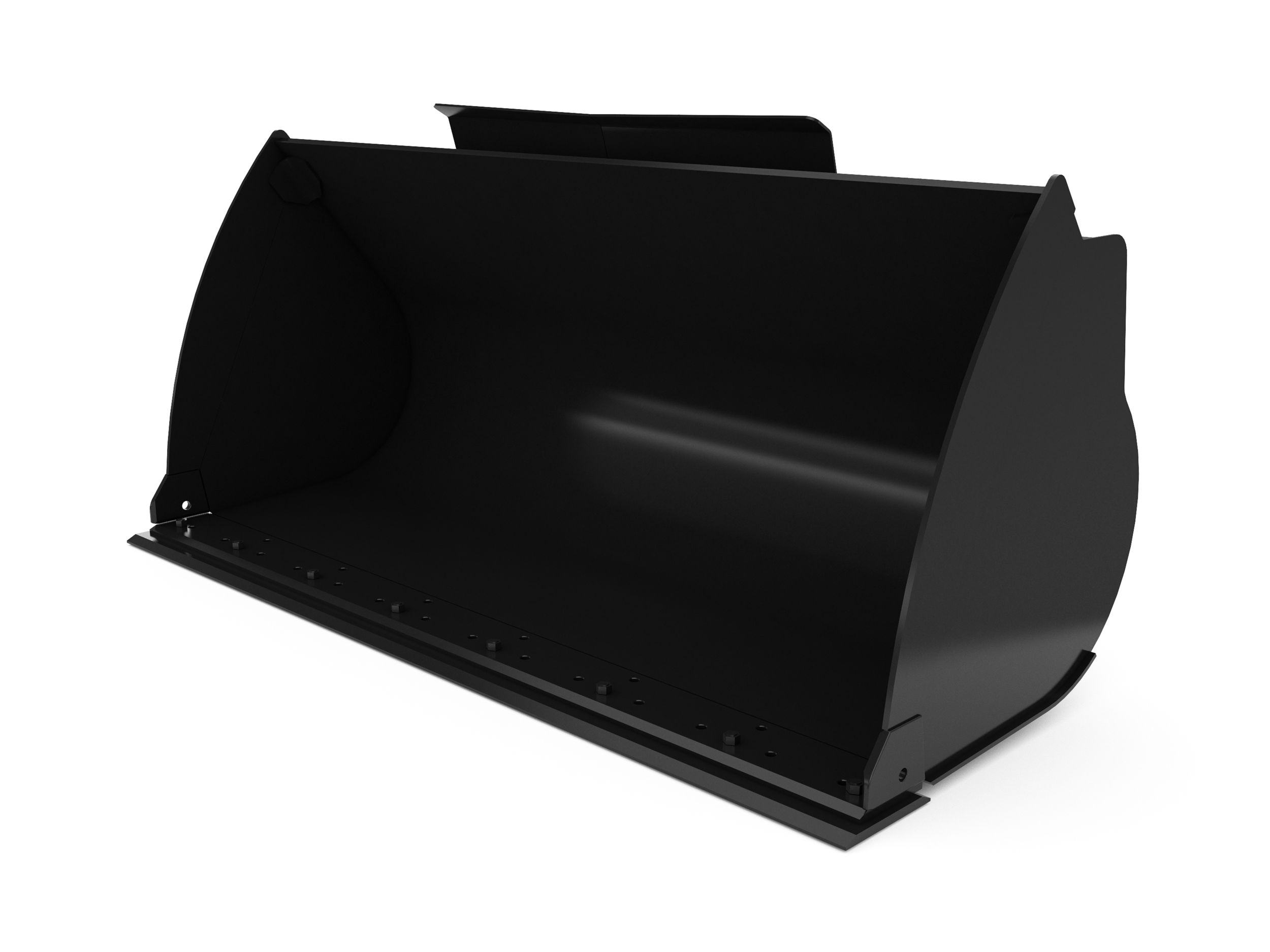

| Bucket Capacities | 1.6-3.5 m3 (2.1-4.6 yd3) 1.6-3.5 m3 (2.1-4.6 yd3) |

| General Purpose | 1.6-1.9 m3 (2.1-2.5 yd3) 1.6-1.9 m3 (2.1-2.5 yd3) |

| Light Material | 2.5-3.5 m³ (3.2-4.6 yd³) 2.5-3.5 m³ (3.2-4.6 yd³) |

| Steering Articulation Angle - Each Direction | 40 ° 40 ° |

| Maximum Flow - Steering Pump | 22 gal/min 82 l/min |

| Maximum Working Pressure - Steering Pump | 2901 psi 20000 kPa |

| Steering Cycle Times - Lock to Lock - At 2,350 rpm | 2.3 s 2.3 s |

| Number of Steering Wheel Turns - Lock to Lock | 3.4 turns 3.4 turns |

| Maximum Flow - Implement Pump | 39 gal/min 148 l/min |

| Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, Standard | 25 gal/min 95 l/min |

| Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, High | 32 gal/min 120 l/min |

| Maximum Flow - Implement Pump - 4th Function, Maximum Flow | 25 gal/min 95 l/min |

| Maximum Working Pressure - Implement Pump | 4061 psi 28000 kPa |

| Relief Pressure - Tilt Cylinder | 4641 psi 32000 kPa |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure | 4061 psi 28000 kPa |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure | 3626 psi 25000 kPa |

| Hydraulic Cycle Time - Maximum Engine Speed - Raise, Ground Level to Maximum Lift | 5.2 s 5.2 s |

| Hydraulic Cycle Time - Maximum Engine Speed - Dump, at Maximum Reach | 1.4 s 1.4 s |

| Hydraulic Cycle Time - Maximum Engine Speed - Rack Back | 2.2 s 2.2 s |

| Hydraulic Cycle Time - Maximum Engine Speed - Float Down, Maximum Lift to Ground Level | 3.7 s 3.7 s |

| Hydraulic Cycle Time - Maximum Engine Speed - Total Cycle Time | 12.5 s 12.5 s |

| Fuel Tank | 40.7 gal (US) 154 l |

| Cooling System | 5.7 gal (US) 21.5 l |

| Engine Crankcase | 2.4 gal (US) 9 l |

| Axles - Front Center Differential | 2 gal (US) 7.5 l |

| Axles - Rear Center Differential | 2 gal (US) 7.5 l |

| Hydraulic System - Including Tank | 25.9 gal (US) 98 l |

| Hydraulic Tank | 14.5 gal (US) 55 l |

| Transmission | 0.9 gal (US) 3.4 l |

| Forward and Reverse - Low Range, Speed Range 1* | 6.3 mile/h 10 km/h |

| Forward and Reverse - Low Range, Speed Range 2* | 12.5 mile/h 20 km/h |

| Note | *Creeper Control allows speed control from a stand still up to 10 km/h (6.3 mph). The Creeper Control will only work in Range 1. *Creeper Control allows speed control from a stand still up to 10 km/h (6.3 mph). The Creeper Control will only work in Range 1. |

| Standard Size | 17.5-25 16 PR (L-3) 17.5-25 16 PR (L-3) |

| Other Choices Include | 17.5-25 12 PR (L-2), 1PC Rim; 17.5-25 12 PR (L-3), 1PC Rim; 17.5R-25, radial (L-3), 1 or 3PC Rim 17.5-25 12 PR (L-2), 1PC Rim; 17.5-25 12 PR (L-3), 1PC Rim; 17.5R-25, radial (L-3), 1 or 3PC Rim |

| Note (1) | Tire options may vary by region. Contact your Cat dealer for details. Tire options may vary by region. Contact your Cat dealer for details. |

| Note (2) | In certain applications, the loader's productive capabilities may exceed the tire's tonnes-km/h (ton-mph) capabilities. In certain applications, the loader's productive capabilities may exceed the tire's tonnes-km/h (ton-mph) capabilities. |

| Note (3) | Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. |

| ROPS | ISO 3471:2008 ISO 3471:2008 |

| FOPS | ISO 3449:2005 Level II ISO 3449:2005 Level II |

| Note (1) | Cab and Rollover Protective Structures (ROPS) are standard. Cab and Rollover Protective Structures (ROPS) are standard. |

| Note (2) | The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, is 77 dB(A). The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, is 77 dB(A). |

| Note (3) | The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC is 103 dB(A). The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC is 103 dB(A). |

| Note (4) | *The measurements were conducted with the cab doors and windows closed. *The measurements were conducted with the cab doors and windows closed. |

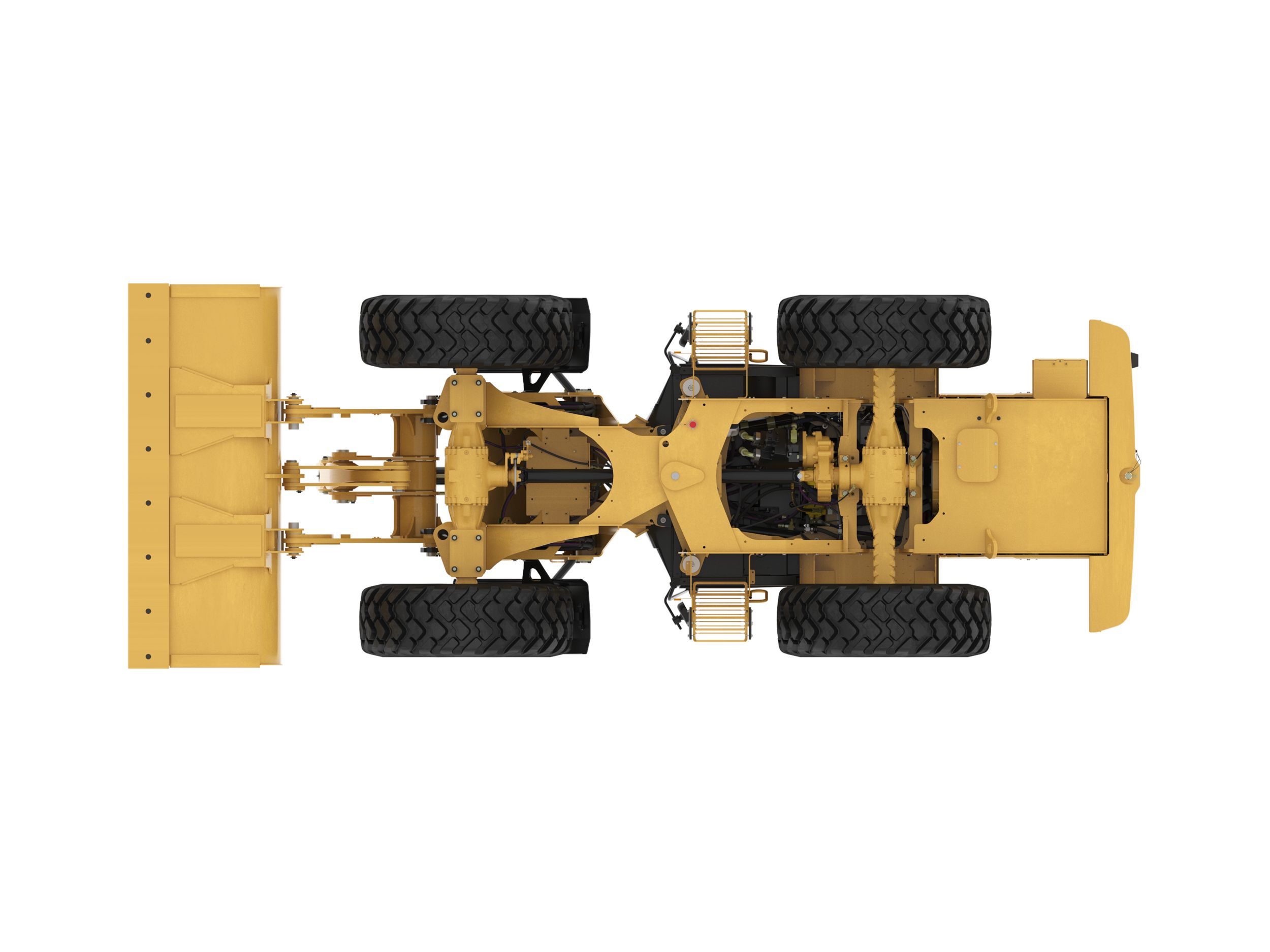

| Front | Fixed; Locking differential (standard) Fixed; Locking differential (standard) |

| Rear | Oscillating ±11 degrees; Locking differential (standard) Oscillating ±11 degrees; Locking differential (standard) |

Advantages and Features

High Performance

With its high full turn tipping loads and breakout forces, the K Series delivers a powerful solution for all customer applications.Ease of Operation

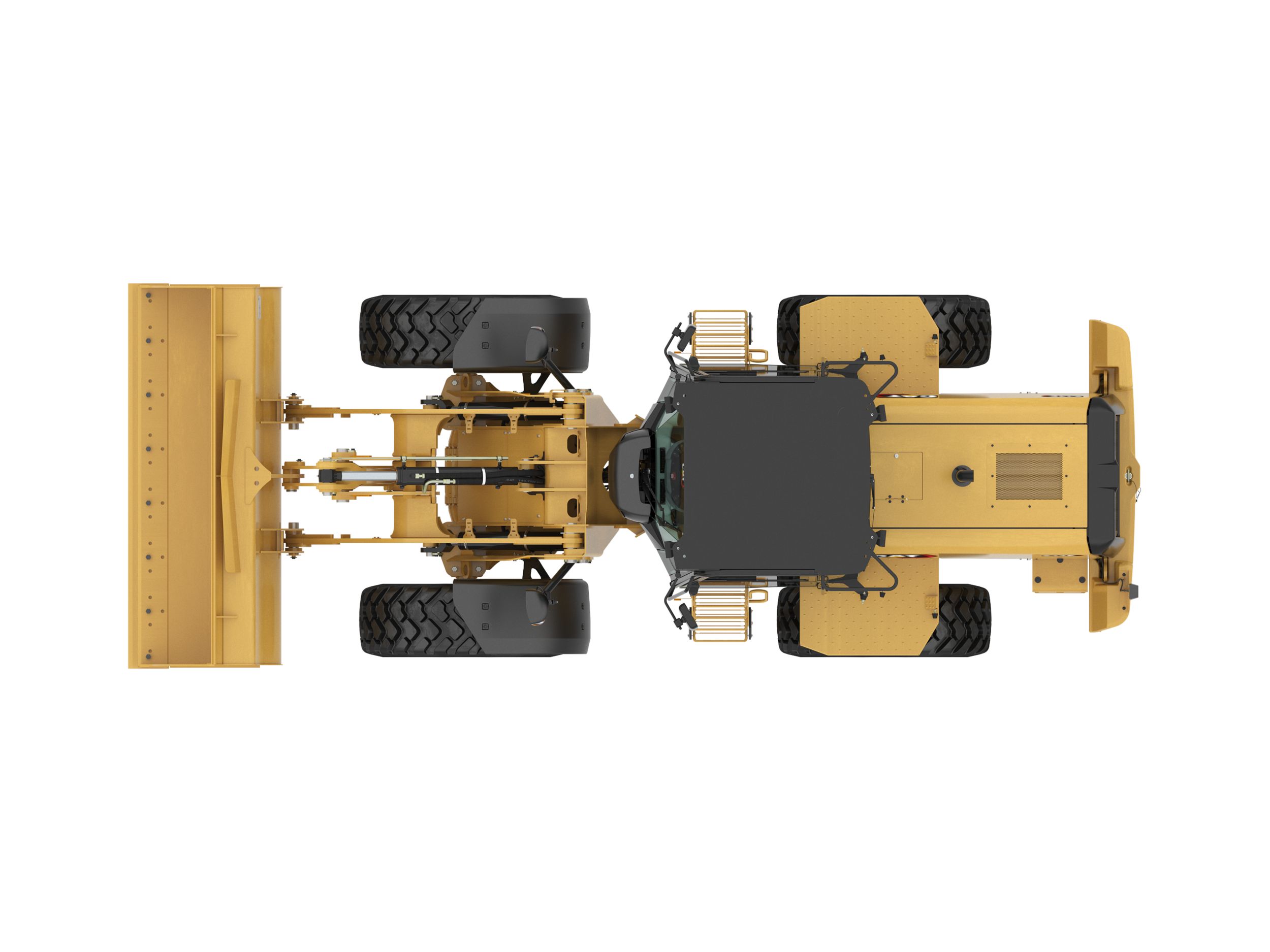

State of the art electro-hydraulic system provides low effort, fine control with fast cycle times. All-in-one joystick helps keep eyes on the work. Operator can adjust machine responsiveness with the push of a button, which allows the operator to set up the machine exactly the way they want it based on the application.Parallel Lift Loader Linkage

The Cat® Optimized Z-bar Loader linkage combines the digging efficiency of a traditional Z-bar with tool carrier capabilities for great performance and versatility. With parallel lift and high tilt forces throughout the working range you can safely and confidently handle loads with precise control.Standard Equipment

-

POWER TRAIN

- Cat C4.4 mechanical engine

- Electric fuel pump with four micron filtration

- S·O·SSM port, transmission oil

- Hydrostatic transmission, 20 km/h (12.5 mph)

- Lubed for life universal joints

- Forward – Neutral – Reverse on joystick

- 100% locking differentials, while moving

-

Brakes, service

– Enclosed, wet-disc full hydraulic

- Brakes, parking (also secondary brake)

- Radiator, serviceable core, single plane

- Air cleaner, radial seal, dual filters

- Air inlet heater starting aid

- Cooling fan, hydraulic

- Radiator expansion tank

- Tires, 17.5-25, 16PR (L-3)

-

LOADER

- Parallel lift, Z-bar loader

- Ground access grease points

-

HYDRAULICS

- Automatic lift kickouts

- Priority steering

- Hydraulics, two valve, one joystick

- Hydraulic diagnostic pressure taps

- S·O·S port, hydraulic oil

- Hydraulic oil cooler – single plane

- Hydraulically driven cooling fan

- Pump, variable displacement piston

-

ELECTRICAL

- 80-ampere alternator

- One 850 CCA maintenance free battery

- Halogen flood lights (front and rear)

- Directional signals (front and rear)

- 12-volt direct electric starting

- Ignition key start/stop switch

- Switch, battery disconnect key

- Product Link™ ready wiring

-

OPERATOR ENVIRONMENT

- ROPS/FOPS cab, pressurized and sound suppressed

- Hydraulic control lever lockout

-

Gauges

– Engine coolant temperature

– Hydraulic oil temperature

– Fuel level

– Speedometer

– Digital hour meter

-

Operator warning system indicators:

– Brake charge pressure low

– Engine malfunction

– Park brake applied

– Electrical system voltage low

– Hydraulic oil filter bypass

– Action indicator

- Interior light

- Door

-

Seat

– Fabric only

– Adjustable height, backrest, armrest

– Seat belt, retractable 51 mm (2 in)

- Heater/defroster

- Wiper/washer front (intermittent)

- Wiper/washer rear

- Tinted front glass, laminated

- Adjustable steering column

- Rearview mirrors, exterior (two)

- Ground level door release

-

FLUIDS

- Extended life coolant antifreeze, protected to –36° C (–33° F)

- Cat Advanced HYDO™ 10

-

CHASSIS

- Fenders, front

- Engine enclosure – lockable

- Recovery hitch

- Vandalism protection – locked service points

- Counterweight

-

REGIONAL STANDARDS (as required)

- Alarm, back-up alarm

- License plate mount

- Serial number, engine block stamp

Optional Equipment

-

OPTIONAL EQUIPMENT

- Integrated Toolcarrier (IT), standard coupler

- Lights, roading, dip

- Lights, cab, working (four)

-

Feature package, load

– Return to Dig, Lift Kickout, Implement Modulation, Throttle Lock, Rimpull Control, Hystat aggressiveness

-

Feature package, road

– Ride Control, Implement Modulation, Throttle Lock, Rimpull Control, Hystat aggressiveness, Creeper Control

-

Feature package, load and road

– - Ride Control, Return to Dig, Lift Kickout, Implement Modulation, Throttle Lock, Rimpull Control, Hystat aggressiveness, Creeper Control

- Seat belt, retractable 75 mm (3 in)

- Heater and air conditioner

- Security system, machine

- Year of manufacture plate

- Beacon, rotating

- Alarm, back-up

- Product Link

- License plate mount

- Tire Options

- Steering, secondary

- Seats (deluxe/premium/vinyl)

- Auxiliary hydraulics (3rd and 4th functions)

- Battery, heavy duty

- Fenders, rear

- Rearview camera

- Radio

- Toolbox

- Rear blind

- Guards (lights, hitch, power train, driveshaft, crankcase)

- Reversing fan

- NOTE: Not all features are available in all regions. See your Cat dealer for more information.