Technicial Specifications

| Maximum Rating | 2420 ekW (60Hz), 3250 kVA (50Hz) 2420 ekW (60Hz), 3250 kVA (50Hz) |

| Minimum Rating | 2200 ekW (60Hz), 2938 kVA (50Hz) 2200 ekW (60Hz), 2938 kVA (50Hz) |

| Emissions/Fuel Strategy | EPA Tier 4 Final, IMO Tier 2 EPA Tier 4 Final, IMO Tier 2 |

| Frequency | 50 / 60 Hz 50 / 60 Hz |

| Speed | 900 / 1000 rpm 900 / 1000 rpm |

| Duty Cycle | Prime, Continuous Prime, Continuous |

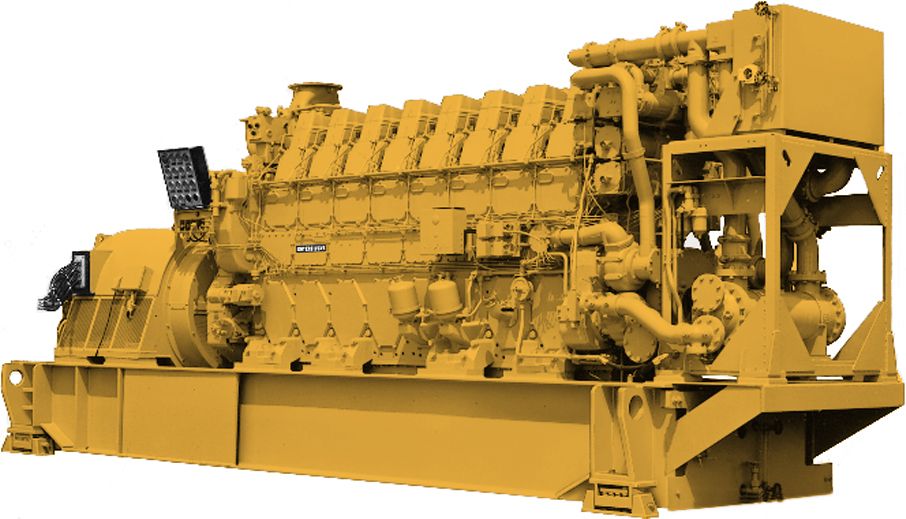

| Engine Model | C280-8, I-8,4-Stroke Water-Cooled Diesel C280-8, I-8,4-Stroke Water-Cooled Diesel |

| Bore | 11 in 280 mm |

| Stroke | 11.8 in 300 mm |

| Displacement | 9064 in³ 148 l |

| Compression Ratio | 13:01 13:01 |

| Aspiration | TA TA |

| Fuel System | Direct unit injection Direct unit injection |

| Governor Type | Generator Set Monitoring System (GMS) Generator Set Monitoring System (GMS) |

| Length - Maximum | 404 in 10261.7 mm |

| Width - Maximum | 99.62 in 2530.3 mm |

| Height - Maximum | 156.6 in 3977.7 mm |

| Dry Weight - Genset (maximum) | 91050 lb 41390 kg |

Advantages and Features

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

Generator

- Matched to the performance and output characteristics of Cat engines

- Industry leading mechanical and electrical design

- Industry leading motor starting capabilities

- High Efficiency

Worldwide Product Support

- Cat dealers provide extensive post-sale support including maintenance and repair agreements.

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries. The Caterpillar S��?�O��?�S��?��?��? program cost effectively detects internal engine component condition, even the presence of unwanted fluids and combustion by-products

Full Range of Attachments

- Wide range of bolt-on system expansion attachments, factory designed and tested Flexible packaging options for easy and cost effective installation

Standard Equipment

-

Air Inlet System <!-- 3600 series only -->

- Aftercooler, fresh water, corrosion resistant coated (air side)

- Breather, crankcase, top-mounted

- Turbocharger, watercooled (720 rpm and HFO), engine oil lubricated

- Air inlet shutoff

-

Cooling System

- Engine coolant water drains

- Jacket water thermostats

- Water temperature regulator

-

Exhaust System

- Includes adapter, flexible exhaust fitting

- 457 mm (18 in) Cat bolt pattern

- Dry, gas tight, exhaust manifold

-

Fuel System

- Simplex or duplex

-

Generator System

- Custom generator per generator data sheet completed by dealer

-

Governor System

- UG Actuator

-

Lube System

- Oil filler and dipstick

- Crankcase explosion relief valves

- Oil pressure regulating valve

- Service side engine mounted on cylinder block inspection covers

- Wet oil sump. Includes engine-driven main lubrication and oil pumps, oil lines and oil pan

- Centrifugal oil filters with single shutoff

-

Mounting System

- Engine and generator mounting

- Damper, torsional vibration

-

Starting / Charging System

- Air silencer

- Vane type air starter

- One motor, engine mounted at rear, on left side

- Line group for single point custom connection

-

General:

- Paint, Caterpillar yellow

- Gear driven pumps: Fuel/oil/jacket water/Aftercooler/Oil cooler water

Optional Equipment

-

Air Inlet System

- Air cleaner louver assembly

- Boost control valve

- Soot filter

- Vertical support bracket

- Heavy duty air cleaner

- Air inlet adapter

-

Cooling System

- Heating aids

- Auxiliary water pump

- Cooling system aids

- Expansion tank

-

Exhaust System

- Weld flange and related hardware

- Flexible exhaust fittings

-

Fuel System

- Fuel priming pump

- Fuel system connections

- Duplex primary fuel strainer

-

Generator System

- 3 Phase, six Leads, WYE

- Class F insulation

- Busbar connections

- Winding temperature detectors

- Anti-condensation space heaters

-

Governor System

- Battery backup/power supply

- EGB actuator

- 2301 A load share

- Electronic/actuators

- Digital programmers

- 723 Plus

-

Lube System

- Oil pan drain valve

- Lube ANSI adapter (Emergency connection)

-

Mounting System

- Spring type vibration isolators

- Isolator

- Vertically restrained

- Non-vertically restrained

-

Starting / Charging System

- Pressure reducing valve

- Compressed air flex hose

-

General:

- Custom paint colors